Men have always been fascinated with making or forging weapons for defense, hunting or war. The red hot iron or steel hammered on the anvil into a knife is especially pleasing.

Knives by H. House, J. House and Sword by W. White

Bag by J. Mills, Measure by F. House

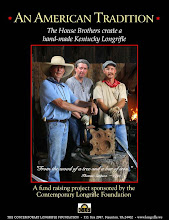

Soon after I went into the longrifle business in 1967 I

began to forge longknives. By trial and

error my blades looked fairly good, but were tempered to soft.

My brothers Frank and John and cousin Willie later discovered my blacksmith shop, anvil and forge and my

woodturning lathe. At that time they

were still in high school. Some students

ran to tell the principal, Darrell Hampton, that the boys were cutting their

last two study periods to run off to Hershel’s gun shop! He said, “they will probably learn more out

there, as they sure as hell aren’t learning anything here.”

Frank and Willie caught right on to forging and tempering

blades. John liked to turn billie clubs, numb chucks and file handles for my gun shop.

Later he took to hammering out blades.

All three of the boys became fine bladesmiths.

I never saw the need or had the energy to hammer out a

swoard blade but Frank and Willie took right to it and completed many fullered,

long blades. When Frank was ready to

temper his first long blade in vegetable oil he aligned the oil trough east to

west. I had heard somewhere, with long

blades subject to warpage, you need to temper south to north or true magnetic

north. Frank said “that makes no sense

it’s just a superstition,” but after two attempts, with the blade warping

badly, he came over to the shop to borrow my compass, so we all learned.

I saw to it that the boys got to Friendship, the primitive

camp and the N.M.L.R.A. range, and they like me were ruined for life.

Frank who for a time worked with me in the rifle shop,

has gone on to be a fine full time rifle and knife smith.

I encouraged Willie to build knives full time and helped him

get a few tools together. He converted a

smoke house into a knife shop and made a good living for many years. He is the only one I know of who forges

beautiful Damascus by hand welding a steel bit in the center of each

blade. He still builds blades part time.

The dirk and sheath was made by J. House.

John has built a nice old timey shop and is a full time

knife smith. He also makes good leather

sheaths for his knives and for some of the knives I make. Twice yearly, John and I teach a very

successful hands on southern mountain rifle building class.

All Knives by H. House

John, Willie and I have recently taught a few hands on knife

forging classes. We work with eight

students, using three coal fired forges and anvils, being careful that no one

gets burned. It is surprising how

quickly most students catch on to forging, annealing, filing, tempering and

drawing the blades. Most fashion a deer

antler handle. Students take home a

complete knife and one or more extra blades.

This a two day workshop. Everyone

works hard but has a good time.

Copy by Hershel House. Photography by Alison Paz.

Flintlock Magazine 2002 Volume 5 Number 1.

Flintlock Magazine 2002 Volume 5 Number 1.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.